written by Rene K. Mueller, Copyright (c) 2007, 2014, last updated Tue, January 20, 2015

4V 4/8 building instruction |

After some pondering, I realized a good procedure to compose the entire dome and then disassemble it again partially again without much overhead.

That's what I came up:

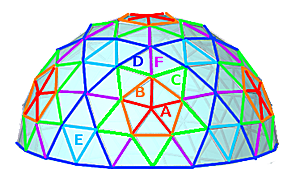

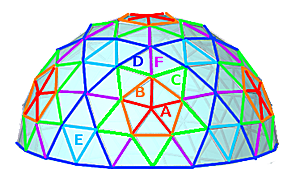

- compose 6x (A+B+C+D+F) entirely together, pre-form them if you want, per composition: 5xA + 5xB + 10xC + 10xD + 5xF

- pitch up: compose A+B+C+D+F compositions with E as well, starting with the top A+B+C+D+F, and working the other 5 compositions around the top one

- take down: disconnect the E triangles, and leave A+B+C+D+F together, and store those six compositions aside

This way I need 10 + 5 + 1 = 16 screws per composition (6x 16 = 96 screws), the final dome requires only 91 screws as common edges reduce those 96.

The main advantage is obvious: I only compose once 250 struts in 6 compositions, once done, I pitch up or take down only 6 compositions (which are expected easy to handle by a single person) plus 10x 3 E triangles.

The estimate height of A+B+C+D+F in my case ~ 2x (F+A) = 2 * (94.5cm + 80.1cm) = ~3.00m

Finished 250 bamboo struts with connectors |

After apprx. 20 hours work of adding the 250 connectors to the bamboo stick/struts by drilling 1500 holes (6 holes per strut: 2 into bamboo, 2 x 2 into connector), the skeleton is finished.

While working I slightly changed the procedure, by cutting the connector pointing as 2nd last step and last step drill final hole-to-hole holes into the connectors.

I have only 3 full length spare 182cm long bamboo left for possible spare D and E struts, and hope not using them - otherwise apprx. 10x 90cm long bamboo which allow me to make spare A, B, C and F struts.

I also noticed using cablebinder below 8°C while binding raises the risk to break them while pulling, so I wonder how the cable binders will behave in the winter with tension of a storm for example - certainly things to look at.

Now I need to wait for a few dry days, and a test to pitch the skeleton for the first time.

I will then measure the diameter more exact in order to calculate the leaf-like cover I will make for it.

I'm also pondering of reusing the rain cover and thermal insulation of the yurt:

- yurt roof rain cover: 7.5m x 7.5m

- yurt wall rain cover: 20m x 2m

- 7.5m / 2 + 2m = 5.75m, which means 0.75m spare, so I could use the rain cover

- yurt roof thermal insulation: 3.4m x 0.35m - 1.4m

- yurt wall thermal insulation: 15m x 1.6m

- 3.4m + 1.6m = 5m, which means the thermal insulation I could use as well, since I don't need to cover the skylight, I even end up with 20cm spare.

so I could actually reuse the rain cover and thermal insulation of the yurt for the geodesic dome as well, terrific - yet, the rain cover won't fit as nicely as a leaf-like fitted rain cover, maybe I end up at least to compose the dedicated rain cover nevertheless.

LDPE connectors added on 30 struts |

Due the some impreciseness in the cutting, e.g off by +/- 2-7mm, I decided the remeasure the struts with the attached LDPE half pipe connectors, and drill the end holes according the precise length to get again as precise as possible (+/- 1mm which is my goal):

The dhole is 2.75cm, which adds to 5.5cm - hole to hole distance:

- A = 74.6cm + 5.5cm = 80.1cm

- B = 87.9cm + 5.5cm = 93.4cm

- C = 87.7cm + 5.5cm = 93.2cm

- D = 93.5cm + 5.5cm = 99.0cm

- E = 97.3cm + 5.5cm = 102.8cm

- F = 89.0cm + 5.5cm = 94.5cm

Working on the struts |

So I follow this procedure per strut:

- drill 1 hole 1.25cm off the both ends into the bamboo sturts

- drill 1 hole 1.00cm off the end of the LDPE half pipe

- attach the LDPE half pipe with a cable binder

- remeasure the total "hole to hole" length and mark the final 2 holes in the LDPE half pipe

- drill the holes accordingly into both LDPE half pipes

- cut the LDPE half pipes (pointing)

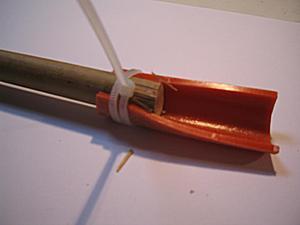

Drilled hole into bamboo

2007/02/14 11:42

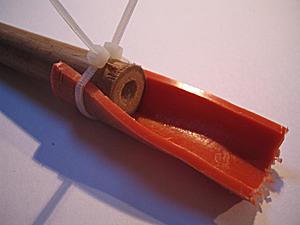

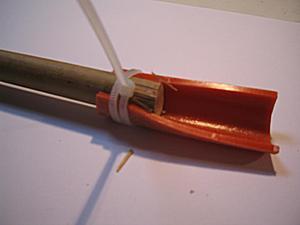

Drilled hole into connector, cable binder fixating connector with bamboo

2007/02/14 11:44

Remeasure entire strut (incl. connector), and mark hole-to-hole, and drill holes then

2007/02/14 11:46

Cut pointing ends

2007/02/14 11:47

It's a bit time consuming this way (assembling 15 struts per hour), but this way I reclaim the preciseness I want to target. Even though the LDPE half pipe is 3mm thick, and most 6-way connectors add 6x 3mm = 18mm variance per 6-way connector, I don't want inpreciseness already in the struts add to the additional expected inpreciseness I cannot compensate that easy or well.

About to cut 250 struts from apprx. 130 bamboo sticks. After 2-3 hours and almost no waste, 250 struts done.

As next I tape the ends before drilling the holes on both ends, and then seal the cut and holes with a finish so no moisture can enter the bamboo.

Aprx. 130 bamboo sticks (182-185cm long, 10-18mm thicker ends), and 15m LDPE pipe (18mm/25mm)

2007/02/03 11:04

Laying out the 60 sticks, marking C+D

2007/02/03 12:08

A, B, C, D, E and F struts cut

2007/02/03 14:04

All endings taped (25mm tape)

2007/02/04 16:23

As I concluded in the notes on the 4V 4/8, 60x C+D, 5x D+D, 30x A+E, 30x B+F gives the least waste.

Where as 2 D determines the longest. As I want to have it closely to 6.4m diameter as my yurt, and the connector tests I made, I have following:

- 2D = 187cm (even though my bamboo is only 182cm) with dhole = 2.75cm, therefore 6.328m diameter:

- A = 74.6cm

- B = 87.9cm

- C = 87.7cm

- D = 93.5cm

- E = 97.3cm

- F = 89.0cm

Now, 2 D = 187cm is longer than my sticks, and I have a total of 139 bamboo sticks, all between 182-184cm, majority 182cm, a few 184cm. So, I'm making 10x D from one stick (wasting 10x 182-93.5 = 10x 88.5cm). So the final cuts (apprx. 5mm per cut away) are like this:

- 60x C+D = 60x 87.7+93.5 = 60x 181.2 (no waste, 1 cut)

- 10x D = 10x 93.5 (10x 88.5cm waste, 1 cut)

- 30x A+E = 30x 74.6+97.3 = 30x 171.9cm (30x 10cm waste, 2 cuts)

- 30x B+F = 30x 87.9+89.0 = 30x 176.9cm (30x 5cm waste, 2 cuts)

total 60+10+30+30 = 130 sticks (5 more than optimal), this gives me 9 sticks spare - which means I need to pay close attention when cutting and especially drilling the holes into the bamboo (only push drilling softly in order to avoid bamboo to split) and I will tape each bamboo end.

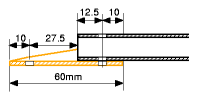

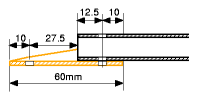

The Connector

The connector will be like this:

Pipe Connector Detail |

- 60mm total length

- common 22.5mm length of the bamboo/LDPE: offset 12.5mm for hole in bamboo

- 1st offset 10mm for 1st hole LDPE (bamboo hole)

- 2nd offset 10mm for 2nd hole LDPE (connecting hole)

- which gives dhole = 60-27.5-10 = 27.5mm

2007/02/02 10:58

2007/02/02 11:00

2007/02/02 11:04

2007/02/02 11:06

Since I have 250 sticks, with 500 endings, and I use half pipe, I require 500/2 * 0.06m = 15m pipe, inner diameter 18mm, 3mm thick therefore 24-25mm outer diameter.

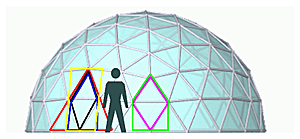

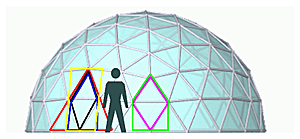

The Door

Door Options for 4V 4/8 |

Not yet decided which door option, most likely yellow option. The pink and green option are too low.

I make the final decision once I put up the skeleton and tried out which one is best.

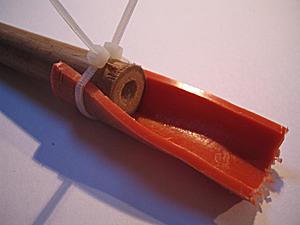

I realized I only need a half pipe, and thereby don't need to squeeze the pipe together, but stretch open the half pipe, also this way save further material.

LDPE half-pipe with 2 cable binders (1)

2007/01/21 15:32

LDPE half-pipe with 2 cable binders (2)

2007/01/21 15:32

LDPE half-pipe with 2 cable binders, connecting (1)

2007/01/21 15:57

LDPE half-pipe with 2 cable binders, connecting (2)

2007/01/21 15:58

So far I made a 3mm holes through the bamboo and the half-pipe, and used two 3mm wide cable binders.

Another more simple binding, with a longer cable binder 3mm wide and wind around 1 1/2 times.

LDPE half-pipe with 1 cable binder (1)

2007/01/22 09:02

LDPE half-pipe with 1 cable binder (2)

2007/01/22 09:02

2007/01/22 09:08

With a M4 screw to connect them then.

Conclusion: using 1 cable binder approach, but with 4mm wide cable binder will do it. I will do some strength / stress tests with weights to see how much pull it can handle.

Next Page >>

Content:

- Page 1: 2014: 5m 2v Icosa, The Numbers, The Details, Connector, Skylight, Door, Cover, Interior, 2006: 6.3m 4v Icosa ...

- Page 2: The Diary, 20. 01. 2015: Little Snow, 18. 01. 2015: A Bit Snow Again, 15. 01. 2015: Struts Replaced & Canvas Put Up Again ...

- Page 3: 20. 2. 2007: Planning Pitch Up, Take Down & Storage, 19. 2. 2007: Completed Struts, 11. 2. 2007: Adding Connectors ...

- Page 4: 18. 1. 2007: Starting with Planning, 10. 9. 2005: Building 4V 4/8 Model, 30. 8. 2005: Building 2V & 3V Model ...