For now I'm still in the early planning stage.

The Dome: Numbers & Material

The dome in numbers & materials:

Star Dome Sketch |

- 6.4m diameter, 3.2m max height

- 17x 10m long bows:

- with PE 32mm diameter, 24-32mm thickness or

- with bamboo 10cm diameter split 6 times, gives 5.1cm wide bamboo split

- rain cover: white PE (leaf-like), 5 leafs (10 halfs to save space)

- interior canvas: raw cotton (leaf-like), 5 leafs (3 lanes/stripes per leaf)

- insulation summer: bubble-wrap (two layers, leaf-like), 5 leafs (3 lanes/stripes per leaf)

- insulation winter: quilted jute blanket with straw or hemp filled and for the winter time, thermal insulated with filled blankets with straw (or hemp), 5 leafs (3 lanes/ stripes/ compartments per leaf)

Leaf-Like Covers

As I pointed out the leaf-like approach for the covers (rain, interior and also thermal insulation) is my preferd choice, with 5 leafs, and as I wrote in Star Dome you can make two halfs for the leaf to orient so that it results in a more narrow lane/stripe.

Rain Cover: leaf geometry 5m long and 4m wide; by composing two halfs, you are able to have length 5m, and wideness 2.83m without extra space for the seam. So, I add some per seam 2cm, this makes 4x 2cm = 8cm, 2.91m total. My source of PE rain cover provides 3.1m wide and 20m long blanket, which gives 4 leafs, the 5th leaf will be 4m x 5m. If I make all 4 or 5 leafs using two halfs, I end up having 10 seams, likely the two fold seam. The last leaf, which is 4m wide gives me 1m extra, which I think is sufficient to have extra space when I make the winter thermal insulation 15cm thick, which means the diameter is 30cm larger, circumference increases by 1m then (0.30m * π). Since the pipes are 3.2cm, and junctions have 4 pipes overlayed each other, makes 4 x 3.2cm = 12.8cm per just knot or junction, which increases circumference by 2 * 12.8cm * π = 80cm each - since we have a couple of such junctions it would make sense to use as 5th leaf 5m x 5m, or have wider leafs in general.

Interior Cover: I have a source of raw cotton, 1.5m wide, 10m long a roll. Per leaf 3 lanes/stripes: 4m + 3.6m + 2.4m ( + 0.6m), the last lane might not be required as there will be the skylight - 10m total per leaf (I may have to add 1-2cm per seam, which makes additional 10cm I should add; since I don't know how the crossing bows behave the total circumference, I like to add extra 5%: 4.2m + 3.78m + 2.52m = 10.50m, for all 5 leafs = 52.50m, it would require 6 rolls; but I'm thinking maybe I can patch a leaf with 10m alone, and reuse the cut-offs, have to think of a good way to do this (illustration follows).

Thermal Insulation: using jute as blanket, and straw or hemp to fill with, source of 1.60m wide lanes of jute I have, but calculating with 1.5m as 10cm will be used for the seam, so 4m + 3.6m + 2.4m (+ 0.6m) (and add 5% to each) - so each lane would be a compartment, to fill the insulator with, plus quilting it each 20-40cm as well.

I either tighten the rain cover to have the thermal insulation not move, or I use ropes outside like in case of the yurt.

Detailed illustrations and photos will follow once I started to build it.

Bamboo-based Skeleton

The original way to do the Star Dome is to use 10cm diameter bamboo, and split it into 6 splits.

The wholesale garden company where I've got my bamboo for the yurt also sells bamboo with 10cm diameter, as decorative bamboo. It's rather expensive (e.g. CHF 70 / &euro 45 a piece).

Pricing / Leftovers

I quickly calculated several options (see in the following diary of 2006/8/26 for more details):

- 6m: 100/120mm bamboo, 6 splits, 5 poles (180m), 1 dome, CHF 355/dome, 2m leftover, 52mm/60°

- 5.2m: 50/55mm bamboo, 4 splits, 10 poles (208m), 1 dome, CHF 200/dome, 0.40m leftover (ideal), 39mm/90°

-

3.6m: 28/30mm bamboo, 2 splits, 50 poles (366m), 2 domes, CHF 43/dome, 1m leftover (ideal), 43mm/180°(due to too small diameter) -

3m: 22/24mm bamboo, 2 splits, 100 poles (600m), 3 domes, CHF 29/dome, 1m too short, or 2m leftover, 34mm/180°(due to too small diameter)

The best is to have 40cm to 100cm leftover used to overlap the splits and bind them together.

The 3.6m long and 28/30mm diameter bamboo seems best in regards price and leftover: 1m left over, 3 pieces bind together, two junctions (1m/2 = 50cm overlapping). With 50 poles I can build two dome skeletons.

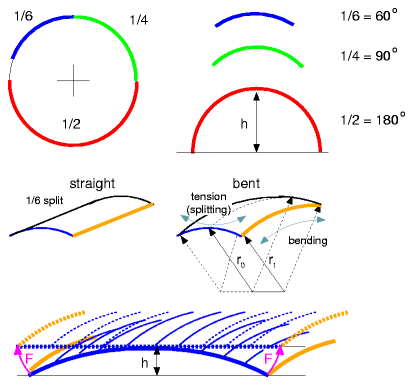

The 6m long is the best in regards of stability, the 6 splits give 5.2cm wide or 60° of 10cm split piece, the likelyness of splitting it again due tension is smallest. To have just 180° increases the chance of additional splits when bent. Tests I made showed that 180° splits split 2 to 3 times when under tension and weaken the overall static.

Tension with Bending within the Split

Let's go into some details of the bamboo split:

Bamboo Split Geometry |

r = d / 2

w = ( (sin(α) r)2 + ((1-cos(α)) r)2)1/2

h = r - (r2 - ( w/2 )2)1/2

Homemade 1/2 Splitter

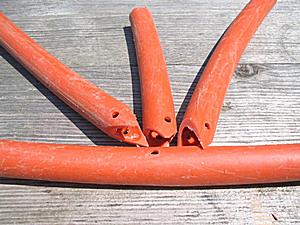

Below some tests I made with bamboo, here first a small homemade splitter. I made a 28mm hole, and put a swiss army knife so the blade faced the inside the hole, and fixated it.

and then I pushed a 3m bamboo 24mm diameter through it:

First I made a test with a thinner bamboo and realized the hole must be just about diameter of the bamboo (plus apprx.4mm), if the bamboo is much smaller than the risk is that it won't split it half as in my test setup, but 1/3 to 2/3 which is not wanted. So I'm thinking to make dedicated bamboo splitters then when I sorted the bamboo. To keep in mind, the bamboo is usually sold sorted, the thicker ends (e.g. 20 to 22mm or 20/22mm), and smaller ends can be quite narrow (not defined really).

Conclusion: I realized with a quick test that 1/2 split the bamboo is too weak and "break", it doesn't really break but creates more splits, e.g. 2 or 3 when under tension and the static is then not suitable anymore, that's why at least 1/4 or 1/6 splits should be used.

Pipe-based Skeleton

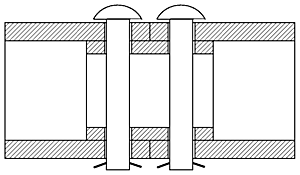

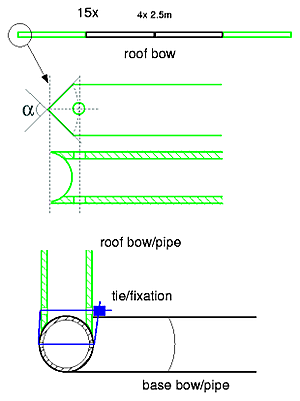

Pipe Junction |

So I choose PE (Polyethylen) pipes, 5m long, 32mm outer diameter, 3mm thick, black. I will cut the 5m into 2x 2.5m long pipes, and combine 4x 2.5m to have a 10m bow then. 17x 10m bow, 17 * 4 = 68 x 2.5m pipes.

In order to cover the black pipe, I thought using cotton to cover all of the pipe: c is 3.2cm * π +10% = 11cm + 0.5cm = ~12cm. Since I have access 1.5m wide and 10m long raw cotton, I can cover 12 bows with such a one roll.

Pipe connecting to the base |

- 15 roof bows:

- 2 x 15 = 30 ends (green)

- 2 x 15 = 30 normal/unaltered (black)

- 2 base bows (8 pipe parts) for the base, unaltered

I'm considering to put a cord through all bows (4 parts), and when the pipe junction is removed so all 4 parts of a bow remain associated.

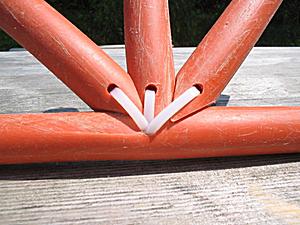

α can vary, e.g. 90° or more narrow if we have multiple bows (like in case of the Star Dome we have three bows per connection) - which the test below should show.

Here a test I made with LD-PE (Low Density Polyethylen) 2.4cm diameter pipe parts:

The middle 90° pipe I cut 45° twice, and the other two pipes I made more narrow. I used simple plastic binder for this test, for a real life application I may still consider it just larger version of it, or metal binder, or use an smart way to bind with a cord.

It also needs to be noted that the test fixation does not provide any stability in regards of angle, vertical or horizontal, it does provide stability for pulling and pushing.

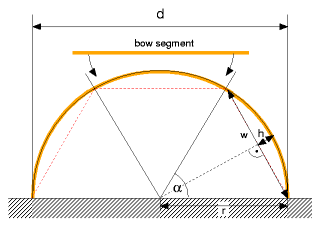

Tension of Bow Segments

Let's look at the full bow, applies to bamboo or pipe too, composed by n-segments, e.g. 3 segments:

Bow Segments Tension |

The formula for the h is the same as above for the bamboo splits, this time it's over full length of the bow:

r = d / 2

w = ( (sin(α) r)2 + ((1-cos(α)) r)2)1/2

h = r - (r2 - ( w/2 )2)1/2

Let's provide a calculator for that (edit the numbers with yellow background and hit RETURN to calculate):

Bow Tension Calculator

More detailed tension I will calculate later, for now h should give already an idea, and w vs lsegment is the length compression applied. I use this calculator to test bow segments of different fabrics: bamboo splits (1/2 and 1/4) and synthetic pipes.

References:

- Elasticity

by J.R. Calvert:

a short article with the math around elasticity

by J.R. Calvert:

a short article with the math around elasticity

Procedure

Since I realized I don't know yet for sure how the circumference is influenced by having 3.2cm diameter pipes, whether by interwaving the pipes diameter remains 6.4m or not, I will acquire the pipes or bamboo first, erect the skeleton of the dome, and measure the overall diameter and radii at each 50cm height (like to do when calculating a free form dome).

I'm still pondering on bamboo and synthetic pipes and make some tests with one bow (10m) with 2-3 segments (5-3m each) with various material - and probably make a bamboo based skeleton and a PVC pipe based skeleton and test it for a couple of months.

Diary

17. 10. 2006: Postponed

Since I'm moving to a new place with my yurt, see my Yurt Diary, I have to postpone further developments on the dome, and continue as soon as possible - either having a working yurt (without thermal insulation) or otherwise a facility to work on the dome.

10. 9. 2006: 1/2 Bamboo Split: Failed

I made two bows composed by three 3.05m 1/2 bamboo splits, when I began to bend the two bows they started to split at the narrow ends of each part, and splitted 2 to 3 times. In other words 1/2 splits are not suitable as guessed.

Conclusion: at least 1/4 or 1/6 are suitable, this implies larger and more expensive bamboo poles.

26. 8. 2006: Bamboo Again

I checked again the bamboo option, I can use large diameter bamboo (e.g. 10cm), split 4 to 6 times as the original StarDome Building Instructions suggests, or use smaller ones and split only once and risk the bending will increase probability of having splits split again lengthwise due the surface tension when I bend the bamboo split.

Here some calculation examples (regarding length and pricing), 17 x 10m bows (170m total):

- 6m long 100/120mm diameter (1 piece CHF 71), with 6 splits I get 6 x 6m (100 &pi / 6 = 52mm)

- 2x 6m = 12m, probably cutting away 2m from each bow as otherwise the dome gets too big (dome 7.6m diameter, 3.8m height),

- total cost of all bamboo (5 poles = 5 x 6 x 6 = 180m) CHF 355 per dome

- 5.20m long 50/55mm diameter, (1 piece CHF 20), with 4 splits I get 4 x 5.20m (50 &pi / 4 = 39mm)

- 2x 5.20m = 10.40m, ideal with 40cm long junction

- total cost of all bamboo (10 poles = 10 x 5.20 x 4 = 208m, which lasts for 1 dome with 38m leftover), CHF 200 per dome

3.66m long 28/30mm diameter, (50 poles CHF 87), with 2 splits I get 2 x 3.66m (28 π / 2 = 43mm, 14mm wide).- 3x 3.66m = 10.98m, very good, using 45cm twice for two junctions

total cost of all bamboo (50 poles = 50 x 3.66 x 2 = 366m, which lasts for 2 domes) CHF 43.50 per dome

3m long 22/24mm diameter (100 poles CHF 87), with 2 splits I get 2 x 3m (22 π / 2 = 34mm, 11mm wide)- 3x 3m = 9m, too short

- 4x 3m = 12m a bit too long, given I use 30cm overlapping, total length 12-0.9 = 11.1m apprx.

total cost of all bamboo (100 poles = 100 x 3 x 2 = 600m, which lasts for 3 domes), CHF 29.00 per dome

I will summarize the results in the first page of this diary.

As found out later, the 1/2 splits are not suitable, that's why these options are not longer an option.

21. 8. 2006: Further Research

I started to contact various companies who manufacture synthetic pipes:

Jansen (Switzerland), 2006/8/21: the head engineer told me during an extensive phone call, that he could not recommend me any material for the usage I described (10m in length, and bent to form 6.4m half bow), and suggested to combine two materials, such as PE with extended UV resistance, plus strength of another material, e.g. bamboo. He also suggested a mix of carbonfiber or fiberglass supported plastic. Yet, the problem of mix of PE or PP with bamboo is that a micro-climate with humidity within the synthetic pipe with bamboo, which could open another challenging issue.

|

- PVC

(Poly-Venyl-Chlorid) with Cold-Support: 2400 N/mm2

(Poly-Venyl-Chlorid) with Cold-Support: 2400 N/mm2

- POM

(Poly-Oxy-Methylen)

(Poly-Oxy-Methylen)

- ABS

(Acrylnitril-Butadien-Styrol)

(Acrylnitril-Butadien-Styrol)

- PC

(Polycarbonat)

(Polycarbonat)

- ASA

(Acryl-Styrol-Acrylester)

(Acryl-Styrol-Acrylester)

Durolaminat (Switzerland): no feedback so far

Geberit (Switzerland): I approached them a few weeks ago already, but they don't sell direct so I had to find a reseller and reviewed the PE 32mm pipe, which was too soft, but for sake of completion: 5m PE 32mm CHF 17.55, for 170m: CHF 603 per dome

30. 6. 2006: Construction Details

Drawing some of the details about how to make the pipe part junctions (4 pipe parts making one bow). As well detail drawing on how the roof bows connect the base bows, either with a tie or another fixation. The holes in the roof bow as well in the base bow/pipe, together with an angle allows any bow to be used at any position for the Star Dome.

13. 6. 2006: Researching Material

So far I researched following materials:Polyethylen (PE): black 32mm pipe, 5m long the pipe, and bends nicely, not too stiff, not too weak, costs CHF 17.80 (CHF 3.55/m), € 11 or US$ 14 per 5m pipe, whereas I need 34 pipes (17 bows a 10m)

Unfortunatly I haven't found any white colored pipes in PE, which I try to find since I saw that heat radiation of the sun passes through semi-transparent layers and those pipe will get get very warm, if not hot when they are black. Another option is the paint them, which I also have to check.

So, the cost of skeleton with PE pipe is about CHF 610 (€ 381, US$ 488)